In the process of manufacturing, transportation, shelf life and storage of flexible packaging, to ensure that the content of the packaging is clean, tidy and free from bacterial contamination, it must be ensured that the packaging is complete, even under stress conditions, it is complete. and it has no weak points, so the packages seal strength and integrity should be tested.

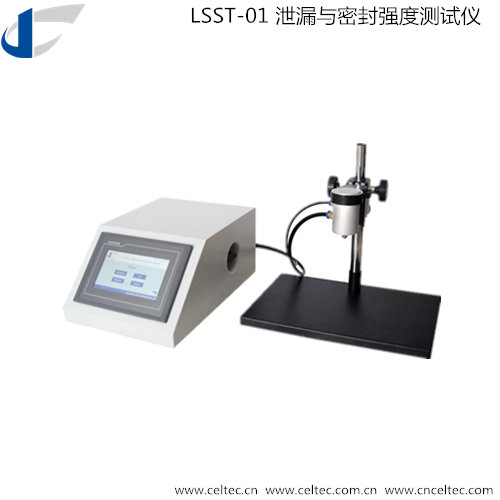

LSST-01 Leak and Seal Strength Tester is an instrument used to check the leak and seal strength (integrity) of packages. It can be widely used in food, medicine, medical, beverage, transportation and other industries in the production process of quality control, selection of raw materials, determination of the most suitable sealing parameters, and confirmation of production machinery and other occasions.

LSST-01 Leak and Seal Strength Tester complies with various standards such as ISO, ASTM and GB. It is suitable for the quantitative determination of sealing force, heat sealing quality, whole bag burst pressure, and sealing leakage performance of each heat-sealed edge of flexible packages formed by various heat-sealing processes, and the Quantitative determination of the sealing performance of various plastic anti-theft bottle caps. Quantitative determination of overall sealing performance, compressive strength, cap body connection strength, burst strength, heat-sealed edge sealing strength, joint strength and other indicators of various hoses; At the same time, it can also be used to measure the compressive strength and durability of materials used in flexible packaging bags. Breaking strength and other indicators, bottle cap twist sealing rate, bottle cap connection firing strength, material stress intensity, and bottle body sealing as a whole. , compressive strength, burst strength and other indicators are evaluated and analyzed.

LSST-01 Leak and Seal Strength Tester

Standards: ISO 11607-1, ISO 11607-2, ASTM F1140, ASTM F2054, ASTM F2096