Application

The flex durability tester is used to measure the resistance against repetitive strain for films, composites and coating films, etc. Flex failure is determined by measuring the pinholes formed in the sample structure. It is also called Gelboflex.

Good flex crack resistance will reduce the propensity of the package developing holes during the distribution cycle thereby destroying the package integrity.

Standard

ASTM F392, “Flex durability of flexible barrier materials”

Sampling and motion

The sample size (200 by 280 mm) is attached to the flex tester mandrels. The flexing action consists of a twisting motion combined with a horizontal motion (compression), thus repeatedly twisting and crushing the film. The test set up gives a twisting motion of 440º in the first 90 mm of the stroke and is followed by a straight horizontal motion of 65 mm. The speed is 45 cycles per minute.

The flexing action consists of a twisting motion combined with a horizontal motion repeatedly twisting and crushing the film. There are 5 pre-programed test conditions to choose from:

- Mode A– Full flex for 1 hour (2,700 cycles),

- Mode B– Full flex for 20 minutes (900 cycles),

- Mode C– Full flex for 6 minutes (270 cycles),

- Mode D– Full flex for 20 cycles,

- Mode E– Partial flex for 20 cycles.

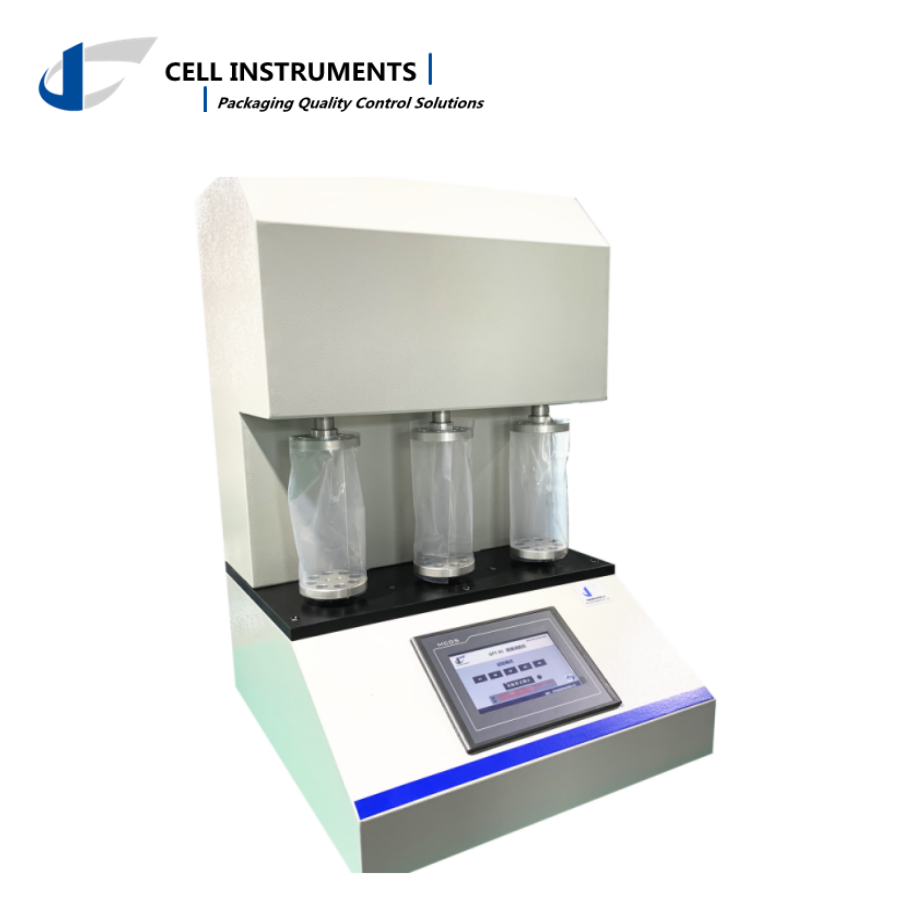

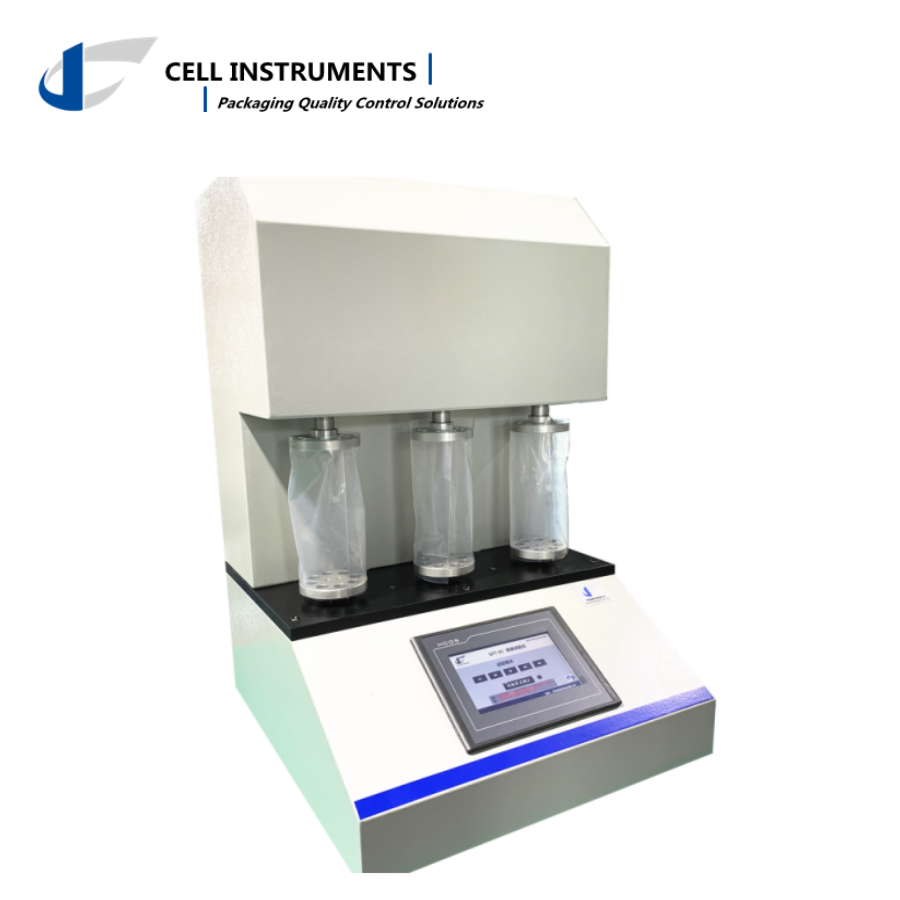

Technical Features

- PLC control and HMI touch screen operation

- 5 standard test modes and 3 test stations

- Long and short stroke fast switching

- Condition A,B,C,D and E can be chosen

Main Parameters

Flex Frequency 45 /minute

Flex Angle 440° (90 mm) or 400° (80 mm)

Capacity 3.5 N.m

Horizontal Stroke 155 mm or 80 mm

Stations 3

Sample Size 280 mm x 200 mm

Power 220V